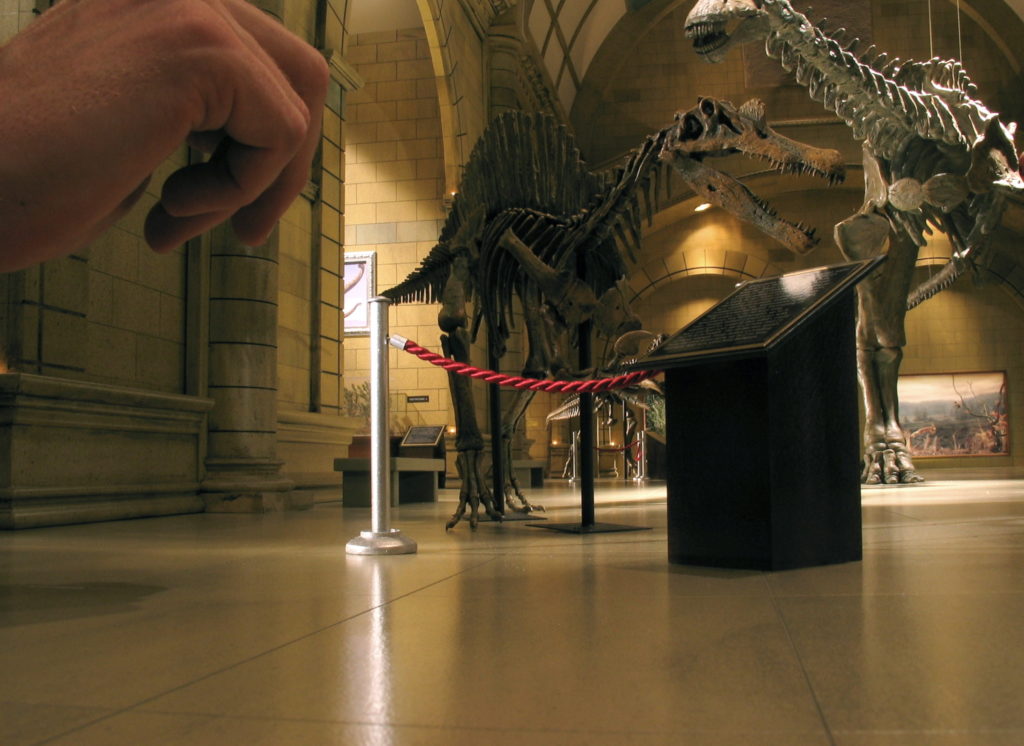

When thinking about the Star Wars universe, “small” is probably not a word that comes to mind. But for Dave Asling, Owner/Creative Director of Creation Consultants, Inc., miniatures and models are perfect for creating larger-than-life visual effects. His company’s work on films such as I, Robot, X-Men: The Last Stand, Fantastic Four: Rise of the Silver Surfer, Elysium and Welcome to Marwen, led Disney+ to tap them for work on Star Wars: The Mandalorian.

While Asling recalls a fascination with model building dating back to his youth in the snow-swept Cavendish township of Ontario, Canada, his career building for film began as a detour from architectural design. What began as a weekend model making project helping a friend out on a tight deadline lead to him eventually running the model shop at a one-stop-shop effects house while learning the hands-on essentials of film production along the way.

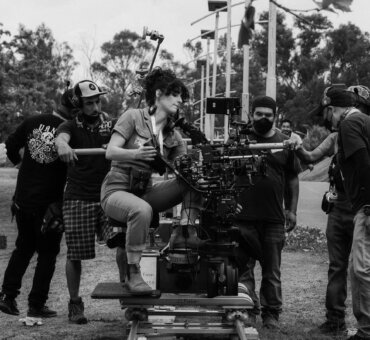

“I got exposed to everything: VFX miniatures design and fabrication, building specialty props and the camera side of things,” he recalls. “That included loading film in the Mitchell camera, learning the fundamentals of motion control, setting lights, and learning the proper way to rig green screens. Most importantly, it meant learning that it wasn’t enough to build something that looked great, – it also had to be designed to photograph properly and tell the story that the director wanted to tell.”

Perhaps just as significantly, Asling observed and was later able to avoid, the many pitfalls that befell other industry vendors who overextended themselves by electing to remain within his principal field of endeavor — the design and fabrication of physical props and miniatures, the latter recently featuring in episodes of the Disney+ series The Mandalorian.

Musicbed: How did Creation Consultants Inc. become involved in The Mandalorian?

Dave Asling: Back in June of 2018, I received an email requesting a meeting to discuss “an innovative new show that would be suited to miniatures.” I arrived for the meeting at a nondescript building in the marina but it wasn’t until I sat down in a small office surrounded by images and designs from the original [Star Wars] trilogy that I realized we were about to discuss The Mandalorian. The plan was for my company to build VFX miniatures which would then undergo 3D scanning and photogrammetry sessions, allowing them to be integrated into the digital pipelines of various VFX vendors. The hybrid physical/digital models would then be ‘played’ behind the actors during live-action photography on massive LED screens, creating fully-realized backgrounds and set extensions that generated and spilled their lighting and reflection data onto the live-action performances.

Do you know what factors led them to consider miniatures as an adjunct to their design plans?

For episode two of the series, production wanted to use 3D scans and photo texturing from various California locations for scenes of a canyon ambush, but they were having a hard time finding a suitable real-world source, and that led them to consider models.

There’s an interior miniature used similarly for a couple of episodes as well?

The production art department had put together really nice renderings that showed the desired aesthetic for the old wooden Sorgan Common House, and with the tight turnaround and the need to have the common house element finished in time for the live-action shooting schedule, it was decided we should build this as physical VFX model. The building was designed to be circular, so we knew there was no need to build more than a third of it — the VFX team could essentially digitally “clone” our work to fill out the various shots. Production’s digital design model gave us dimensional information but no details beyond the curves and basic layout of the structure, so it was up to us to figure out how things were constructed on Sorgan.

We built most of the model from natural materials, which conveyed an imperfect and organic feel. By steaming wood, it could be bent into the desired shape and then lashings of scale rope would bind the bent wooden elements into a rigid structure. Knowing this model was intended for scanning and photogrammetry, we approached it differently than we would a traditionally filmed VFX model, creating “wild” pieces in layers that could be removed to facilitate scanning. On the inside, there was a latticework of woven wicker fencing, followed by a clapboard layer, and then another latticework beyond that. The main structural beams and timbers were rigidly bound together, but these other layers had to be able to separate because one would occlude the next when scanned.

The switch from creating miniatures intended to be shot on-camera to models used for scanning has to have had some impact on your business.

It definitely has. We actually have more freedom to create with this hybrid approach of combining miniatures and digital and I think it’s opened us up to a larger world of potential clients. Versions of the technology have been with us in some form or another for twenty years, though it only became a major part of our business during the last few. In the faster-paced environment of modern production, there’s more of a tendency towards the “we can fix it in post” mindset. That reflects a tendency to want to tinker with things all the way to picture-lock, even though it flies in the face of proven knowledge that if you don’t get things worked out in advance, you’re going to spend a lot more down the line.

Whereas previously, the filmmakers had to commit to a specific visual approach in advance?

And stick with it, which requires discipline on the part of the director and his creative team. Scenes would be boarded and planned, with models built to achieve specific effects, often just from a few limited angles. By using scanning and photogrammetry, we’re now in a place where we get the best of both worlds. We’re able to integrate spectacular physical miniatures into the digital pipeline in a way that doesn’t box the director into limited creative options in post-production.

Considering the various challenges that can and do arise, how do you choose your crew? Is it based on having a “top gun” in each discipline, or a combination of factors?

We’re mostly a team of generalists. When engineering something special like a custom motion-control rig or a particularly complex digital model, you’d certainly want to hire specialists, but more often than not, I wind up doing both the design and engineering of the project myself and then assigning the various parts of the build to my artists. Some of the team might come from a particular area of strength, whether that’s sculpting or electronics or woodworking or painting, but as a rule, I tend to hire artists who have specific strengths but are flexible and interested in expanding their skillsets.

When did you begin expanding into specialty props?

There was a transitional period in the early-00s when visual effects work really began to swing fully into the digital arena, and at that point, the company had to look for alternative revenue streams. By 2009, probably 95% of our work was prop-related, with our project count leaping up to as many as 200 individual builds per year. By then I’d relocated to Vancouver, which was a hub for sci-fi TV production. Since I love science fiction, that work was great fun.The pendulum has swung back the other way again, with the bulk of CCI’s projects once again being VFX miniatures, now designed for scanning and photogrammetry.

Were you working from supplied designs or providing your own?

It depended on the production. V, for instance, had a really great art department that always managed to stay a couple of episodes ahead and delivered very nice renderings. On some productions, a propmaster would provide verbal breakdowns and a pencil sketch, so you could bang out a quick design for them, get it okayed and start construction. Other shows operated under tighter time constraints, which let me get very creative. When you hear, ‘do something that looks cool,’ it can really spark you. Most were hero prop work filling the frame in closeup – it couldn’t be a Nerf gun somebody just sprayed silver. Most clients approached us when they wanted that higher level of detail, which we were already used to with our miniature work.

So you could let your imagination go for some spaceship prop, and temper that with the practical knowledge that it would have to accommodate a battery or cord?

Many of the propmasters that we dealt with came from hands-on backgrounds themselves and understood what they could reasonably expect from us in a limited timeframe with the technology then available. So it was often, “what can we do with a couple of servos, a 9-volt battery, and some blinking lights?” 3D printing wasn’t yet a thing when we got heavily into props, so often we’d just be scrounging from what’s on hand, often kit-bashing from model kit parts, similar to how we’d detail a miniature.

Dive in further on production design by reading our interview with art director Carl Sprague. (Yes, the Carl Sprague that works with Wes Anderson, Steven Spielberg, Martin Scorsese, and other countless Hollywood legends.)